Engineering

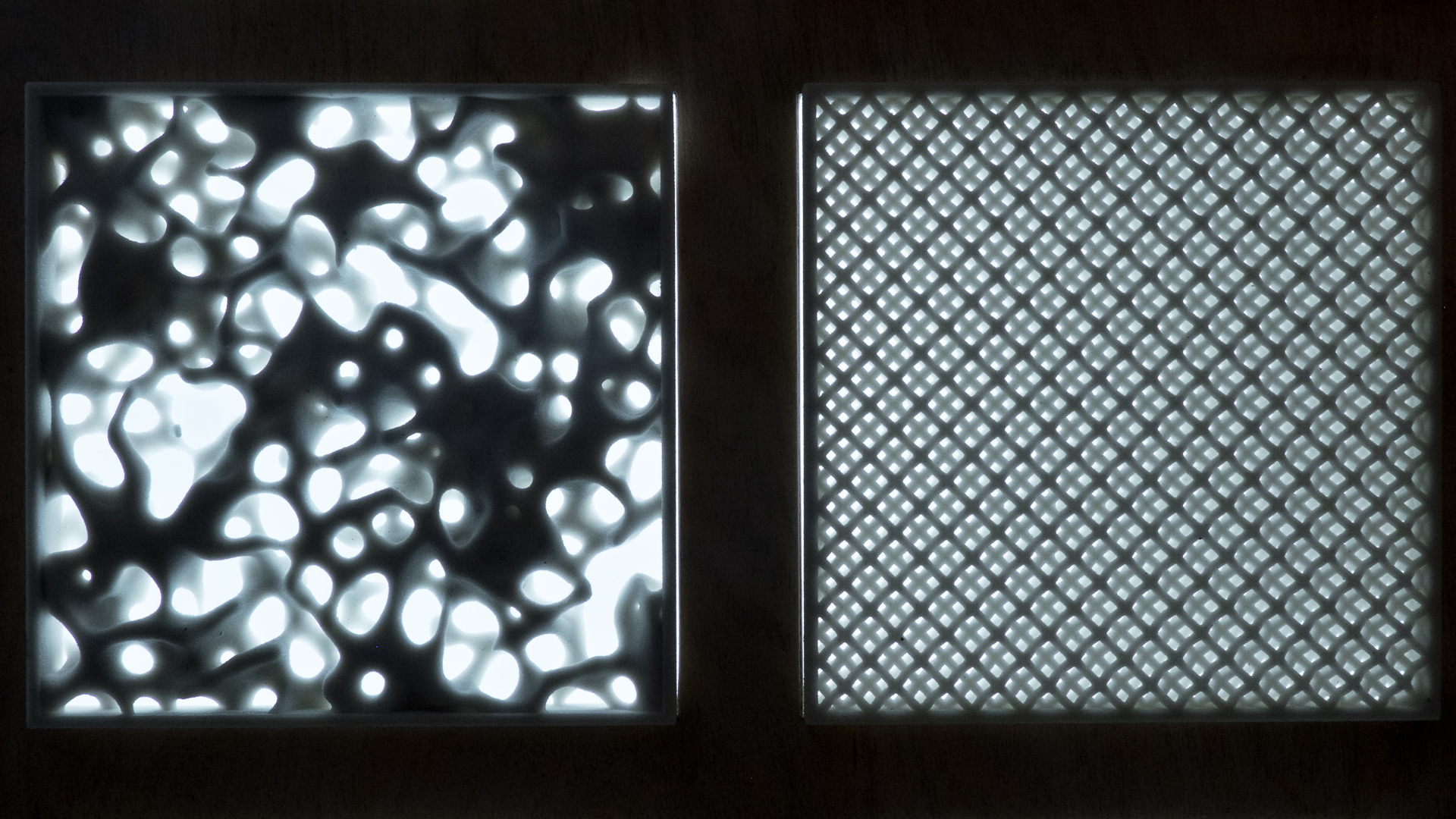

Complex geometry used to come at an unrealistic cost. Through the use of algorithmic design we are able to deliver high-end geometry with previously unattainable complexity. Leveraging additive manufacturing we can make objects lighter, stronger and with variable physical properties. Our advancements are centered around digital manufacturing, simulation based geometry and micro-scale feature control.

Approach

Industry 4.0 is a term often used today, but what does it actually mean to design for this future industry? We believe a shift to digital manufacturing will enable decentralised production, with less waste and higher complexity. Digital manufacturing decouples complexity and cost. Using additive manufacturing to make a cube is likely more costly than making an intricate lattice structure. Designing for these digital manufacturing methods is often still heavily based in older methods. Our algorithmic methodology is specifically set-up to leverage the advantages of digital manufacturing above and beyond what traditional Computer Aided Design (CAD) offers.

A key opportunity that algorithmic design offers in engineering is simulation based geometry. We can grow geometries in simulated environments and in doing so design for very specific conditions. By varying the simulated environments we don't just deliver one design, but a varied set of site-specific geometries for a given context.

Optimisation and iteration

Topology optimisation is very one-dimensional approach to algorithmic design. We argue that there are significant gains to be made in a less absolute approach. Achieving significantly lighter or stronger geometry does not require perfect optimisation; several faster simulations in conjunction with mechanical and functional testing of physical prototypes enables for rapid iteration and optimising for a whole set of variables and properties outside the scope of typical Finite Element Analysis (FEA) or Computational Fluid Dynamics (CFD) simulations.

Development

We don't only have to capacity to design complex geometries, but also to test that they work. We can integrate FEA, CFD and Mechanical Testing into project development throughout the process.

Lastly our capacity to deliver in a wide range of materials ranging from titanium to ceramics leverages the true breadth of additive manufacturing.